Bruising is a persistent problem plaguing the blueberry industry. At this time, fruit damaged by mechanical harvesting should not be sold to the fresh market. This hinders export opportunities and forces the industry to rely on expensive labor for handpicking that can be difficult to access.

Dr. Changying “Charlie” Li, Co-PI and Professor at the University of Georgia, and his team are endeavoring to help solve this problem. They are developing methods to evaluate internal bruising of blueberries using imaging methods in an attempt to find genotypes and cultivars more resistant to bruising.

“We try to use imaging methods to quantitatively measure internal bruising. I think internal bruising for blueberries is a challenging problem. Blueberries are dark in color. And it’s very difficult to visually assess bruised tissues through this dark-blue skin,” Li said.

This internal bruising occurs because of the mechanical impacts sustained when being harvested by standard machine harvesters. According to Li, enzymatic reactions in the tissue cause the fruit to become discolored, but a human cannot see that damage readily through the skin of the blueberry.

“My group has developed one imaging method through a prior project,” Li said. “We used hyperspectral imaging, either through reflectance or transmittance, to detect internal bruising, and we achieved a certain success.”

Hyperspectral imaging (HIS) is a technique that utilizes a wide spectrum of light instead of the usual red, green, and blue in image pixels, allowing for an examination of an object in physical or chemical changes that cannot be seen by RGB images.

“The reason that this method works is, through mechanical impact, certain blueberry fruit cells will rupture, and free water will be available. And under free water we have different absorption [of the light] than intact cells,” Li said. “And I think we will improve the visibility through reflectance and transmittance hyperspectral imaging, so we can spot and quantify the internal bruising.”

In addition to this method Li and his team developed earlier, they are also trying to explore other new methods.

“The first one is called a 3D hyperspectral,” Li said. “Basically, we shed structured light onto the fruit surface. Structured light means it has certain patterns, and then we use another camera to detect this pattern. And then from this we can derive the shape of the fruit. So basically, we can get a 3D shape of the fruit through a single camera whereas typically at least two cameras are needed to perceive the 3D shape of an object.”

The hyperspectral data they collect will have three-dimensional spatial information that helps the team to correct for optical effects caused by the shape of the spherical fruit surface.

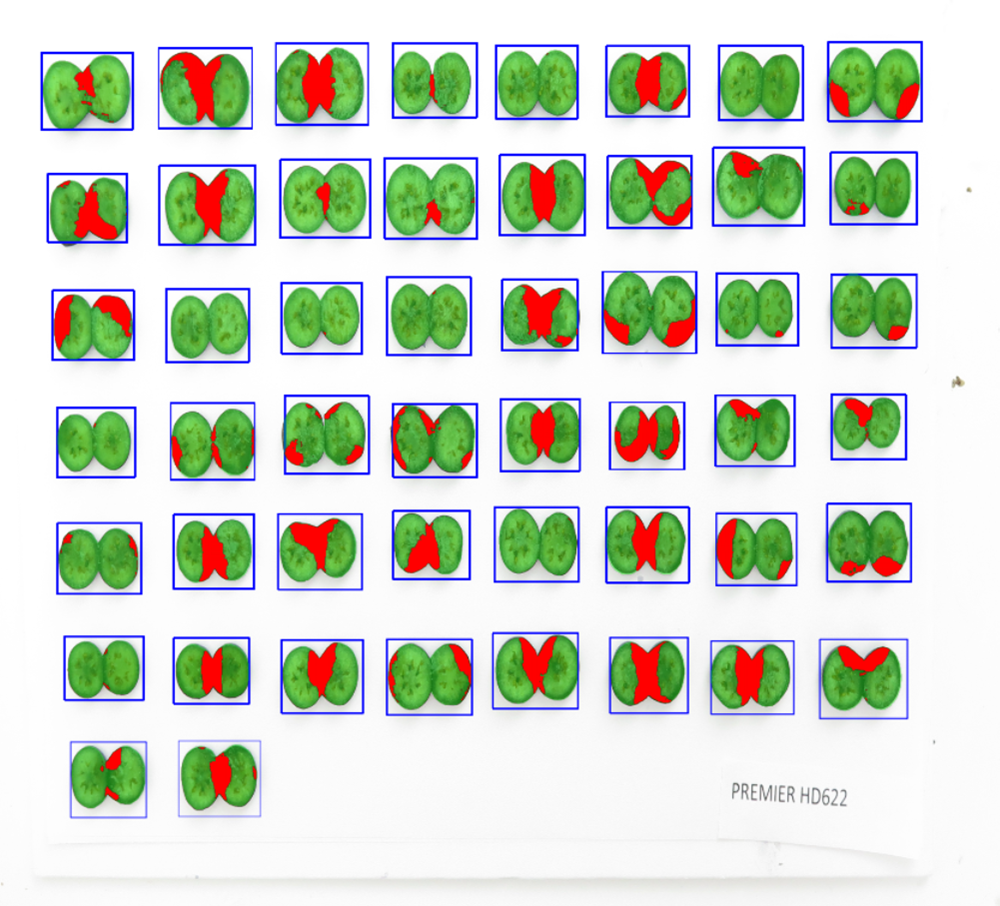

Another technique Li and his team are exploring is to quantify the discolored bruised area of a sliced fruit using artificial intelligence (AI). Currently, evaluators take RGB images and rank this bruising by observing the discolored area through a slice—but it is very subjective. Others use Photoshop or other imaging software where they can mark up the discolored area and then calculate the bruise ratio over the entire surface.

“But this is a very laborious and time-consuming process,” Li said. “My lab is trying to use machine learning—a subset of artificial intelligence to analyze images very quickly and accurately to quantify internal bruising in a few seconds or a fraction of seconds, so we can get all these 50 samples in a batch to get analyzed.”

Most blueberries are handpicked for the fresh market, but this is very expensive because of labor prices and limited availability. But standard mechanical harvesters that promote harvest efficiency create impact damage to fruit and fruit develops internal bruising. Li cites that as much as 78% of fruit harvested by mechanical harvesters have severe bruise damage, affecting growers’ bottom line.

“This is an economic issue; this is also food quality issue. Consumers will not get very high-quality blueberries if they experience too much excessive internal bruising,” Li said. “That’s why I think through this current project, we try to develop better cultivars and genotypes that are more resistant to this internal bruising. And my technique is trying to quantify this internal bruising more accurately and more effectively.”

Bruising is not just a static issue, according to Li. Internally bruised fruit has a shorter shelf life, and consumers are less likely to buy low quality food that is soft and visually unappealing. Li also notes that bruised fruit can favor certain fungi and other postharvest diseases, reducing the economic output. Dr. Lisa Wasko DeVetter, Co-PI and Associate Professor at Washington State University, says that bruising in the Pacific Northwest and elsewhere can limit export opportunities for fresh market fruit.

“It can limit our opportunities for export markets where fruit will have to be in a shipping container for a longer period of time,” DeVetter said. “We’d like to have high quality fruit with less bruising that can last for those long shipping routes and still maintain good quality for those customers.”

Li is currently working with his collaborator, Dr. Penelope Perkins-Veazie, a postharvest physiologist at North Carolina State, who collected fruit samples for them to analyze as images. After quantifying the internal bruising, this data will be provided to geneticists to use in the selection of genotypes less prone to internal bruising.

“I also think the data could be useful for machine designers or machine manufacturers to try to improve their machines to reduce internal bruising. And if we can easily, very quickly identify and quantify those internal bruises, we can improve the machine design,” Li said.

Working together as an interdisciplinary team is key to accomplishing this goal.

“We want to advance mechanical harvesting of fresh market blueberries to adjust for labor shortages and high costs of harvesting in the blueberry industry,” Li said. “Current mechanical harvesting technologies create excessive internal bruising. So that’s why I think through this interdisciplinary research project, we engineers work with horticulturists and other plant scientists together to rapidly quantify internal bruising. We can then select the best genotypes to complement new machine harvest technologies, provide advice for growers, and eventually increase the economic sustainability for the blueberry industry.”